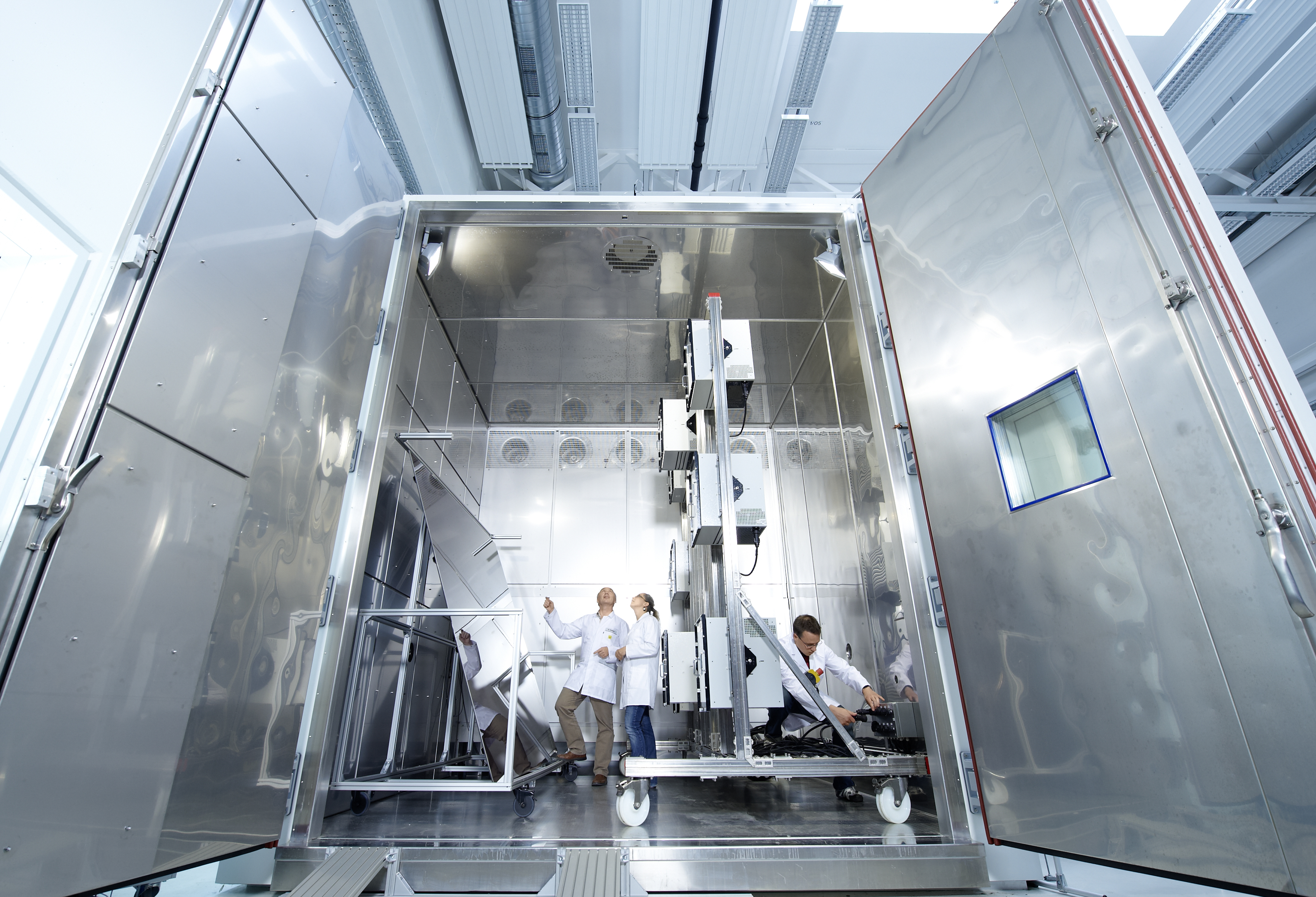

To assess the aging and weather resistance of PV modules, we examine impacts that have an effect on degradation under defined test conditions. At the Fraunhofer CSP few carry out standard climatic tests as defined by IEC 61215:2016 and extended tests individually specified by our customers, or combinations of the standard tests. We have climate chambers of various sizes at our disposal to examine the aging of materials, components and complete modules.

Fraunhofer Center for Silicon Photovoltaics CSP

Fraunhofer Center for Silicon Photovoltaics CSP